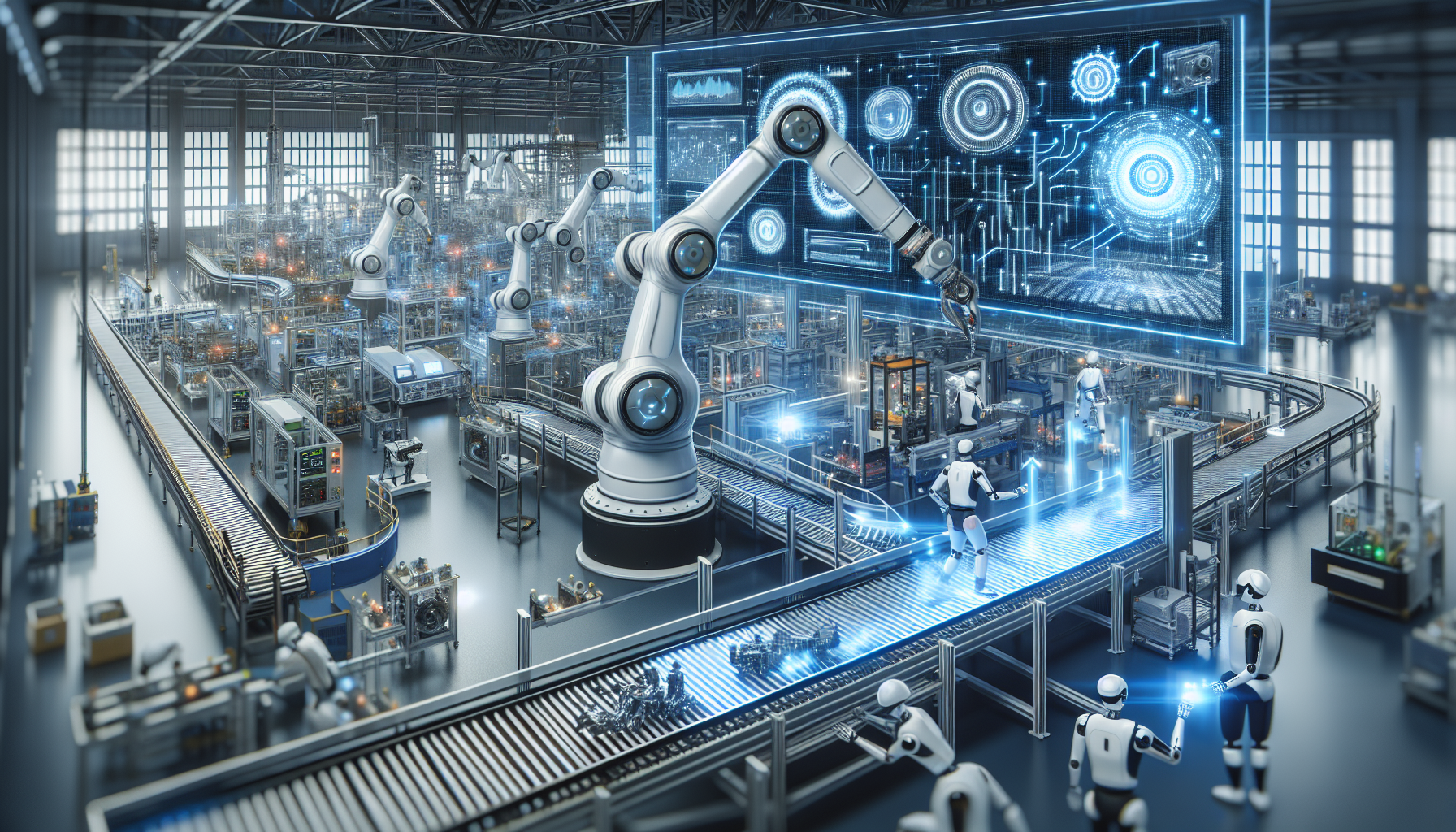

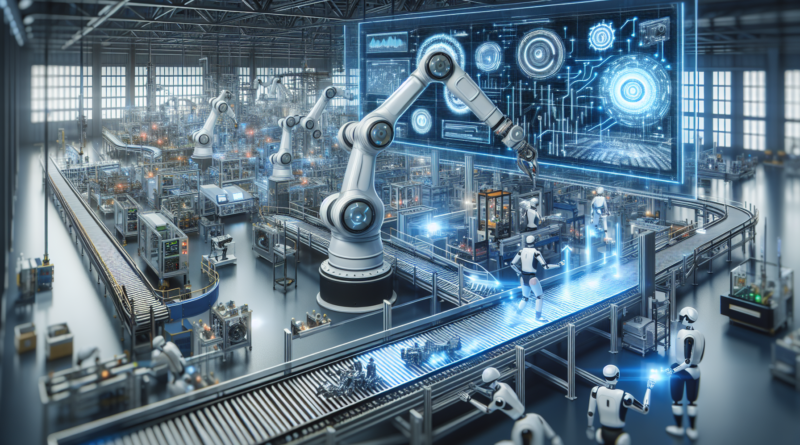

Understanding Smart Factories

A **Smart Factory** is a highly digitized and connected production facility that relies on smart manufacturing. It utilizes advanced technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), and big data analytics to enhance manufacturing processes. These technologies enable real-time monitoring, autonomous decision-making, and seamless integration across various production stages.

Key Components

Technological Backbone

The backbone of a Smart Factory consists of several key components:

– **AI and Machine Learning**: These technologies enable predictive maintenance, quality control, and process optimization.

– **IoT Devices**: Sensors and connected devices collect and transmit data across the factory floor.

– **Big Data Analytics**: Analyzing large volumes of data helps in making informed decisions and improving efficiency.

– **Cloud Computing**: Facilitates data storage and processing, allowing for scalability and flexibility.

Benefits of Smart Factories

Smart Factories significantly enhance **efficiency and productivity** by automating repetitive tasks and optimizing resource utilization. Real-time data analytics allow for quick adjustments to production lines, reducing downtime and waste.

Quality Improvement

Enhanced Quality Control

With AI-driven quality control systems, Smart Factories can detect defects early in the production process. This leads to higher quality products and reduces the cost associated with recalls and rework.

Flexibility and Customization

Adaptable Manufacturing

Smart Factories offer greater flexibility, enabling manufacturers to quickly adapt to changes in demand and customize products. This adaptability is crucial in today’s fast-paced market, where consumer preferences are constantly evolving.

Smart Factory Revolution

The Smart Factory revolution is transforming the manufacturing landscape, offering unprecedented levels of efficiency, quality, and customization. Embrace the future of manufacturing with AI and IoT!

Challenges and Considerations

Transitioning to a Smart Factory involves several challenges, including high initial investment costs, the need for skilled personnel, and potential cybersecurity risks. Companies must carefully plan and execute their digital transformation strategies to overcome these hurdles.

Data Security

Protecting Sensitive Information

As Smart Factories rely heavily on data, ensuring data security is paramount. Implementing robust cybersecurity measures is essential to protect sensitive information from breaches and unauthorized access.

Workforce Transformation

Reskilling and Upskilling

The shift towards Smart Factories necessitates a transformation in the workforce. Employees need to be reskilled and upskilled to work alongside advanced technologies. This includes training in data analysis, machine operation, and maintenance of IoT devices.

Overcoming Challenges

While the transition to Smart Factories presents challenges, strategic planning and investment in workforce development can pave the way for a successful digital transformation.

The Future of Manufacturing

Smart Factories are at the forefront of sustainable manufacturing practices. By optimizing resource use and reducing waste, they contribute to environmental conservation. Furthermore, continuous innovation in AI and IoT technologies promises to drive further advancements in manufacturing.

Global Impact

Transforming Industries Worldwide

The adoption of Smart Factories is transforming industries worldwide, from automotive to electronics. By enhancing competitiveness and fostering innovation, Smart Factories are reshaping the global manufacturing landscape.

Embrace the Future

The future of manufacturing lies in Smart Factories. Embrace this transformation to stay ahead in the competitive global market and drive sustainable growth.

**Smart Factories represent the pinnacle of modern manufacturing, integrating AI and IoT to revolutionize production processes. By understanding their components, benefits, and challenges, businesses can effectively navigate the path towards a smarter, more efficient future.**